|

A dry climate is best. Kevin Jonathan Lee's violin shop is located in the center of this photograph. |

The wood must hang with dry air circulating freely around each piece for at least 7 years. |

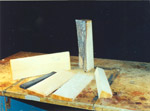

Wood for a violin: Spruce (belly), maple (back, ribs, scroll) ebony (fingerboard) |

Templates for the outline and scroll, with traditional "inside" mold. |

Maple and spruce; jointed and glued for the back and belly. |

|

Blocks glued to mold. Ribs cut, planed and scraped to thickness |

Ribs, bent to the shape of the mold and ready to be glued. |

Gluing ribs onto mold (they are only glued to the blocks). |

Linings are cut, scraped and bent to match the mold and ribs (belly and back). |

Linings moritsed into blocks and glued. |